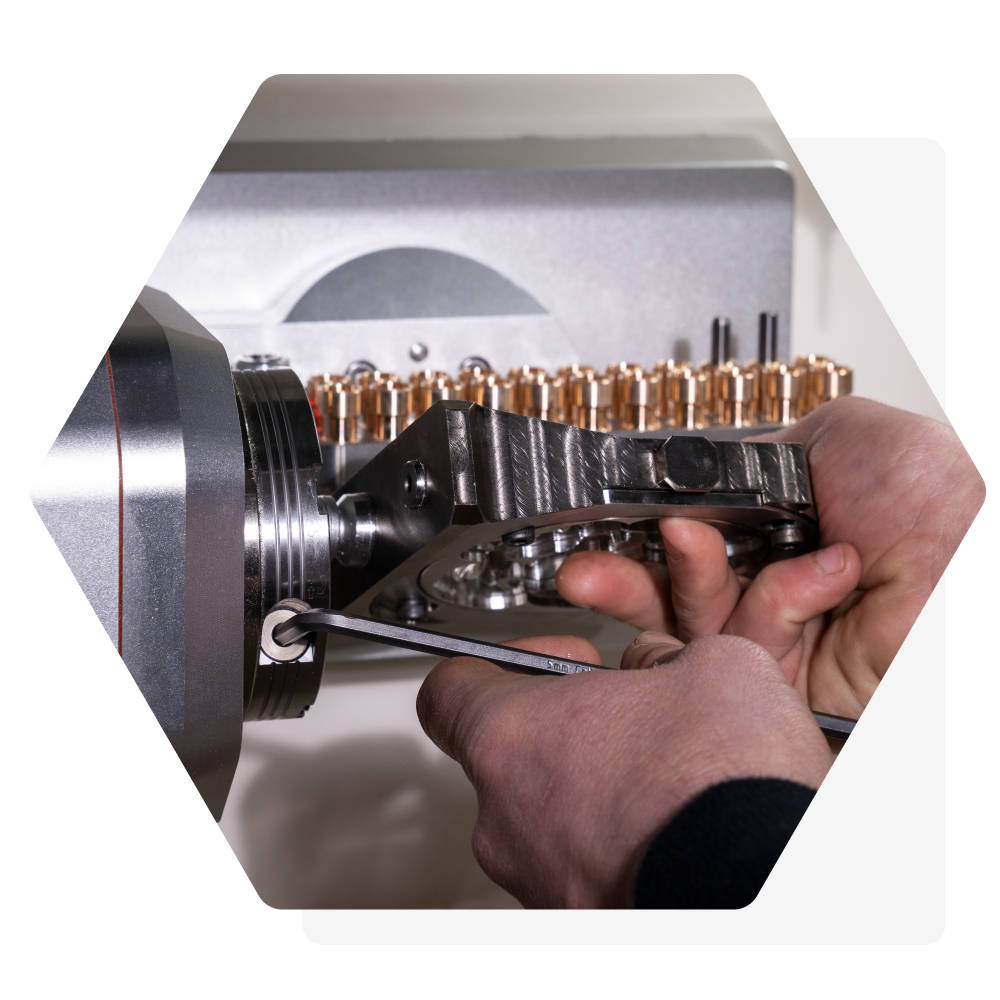

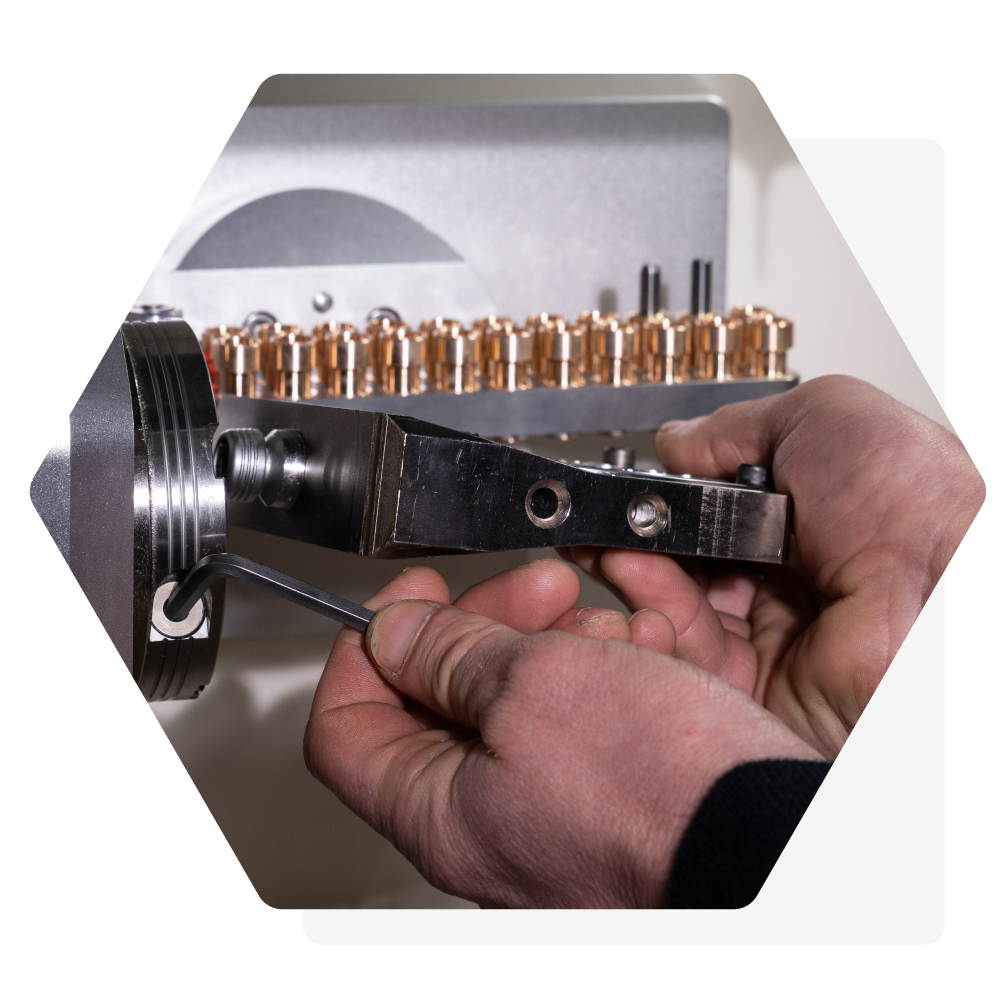

Mechanical quick pod release

Flexibility. Precision. Productivity.

This system enables the removal and repositioning of the pod support with absolute accuracy — even after a paused process.

When combined with the Stop&Go feature, ongoing work can be temporarily interrupted to load a different task or material, with the ability to resume the original process at a later time without losing precision.

In metal milling, the pod and wafer can be extracted mid-process for inspection on the bench. If needed, additional refinements or corrections can be carried out before continuing.

The quick pod release also supports specific pod types tailored to different materials and workflows, such as:

- Closed Pod for heavy-duty metal machining

- C-Clamp for 90° milling and high-precision aesthetic work

This approach ensures greater workflow flexibility while maintaining consistent, high-quality results.